Jan 10, 2025

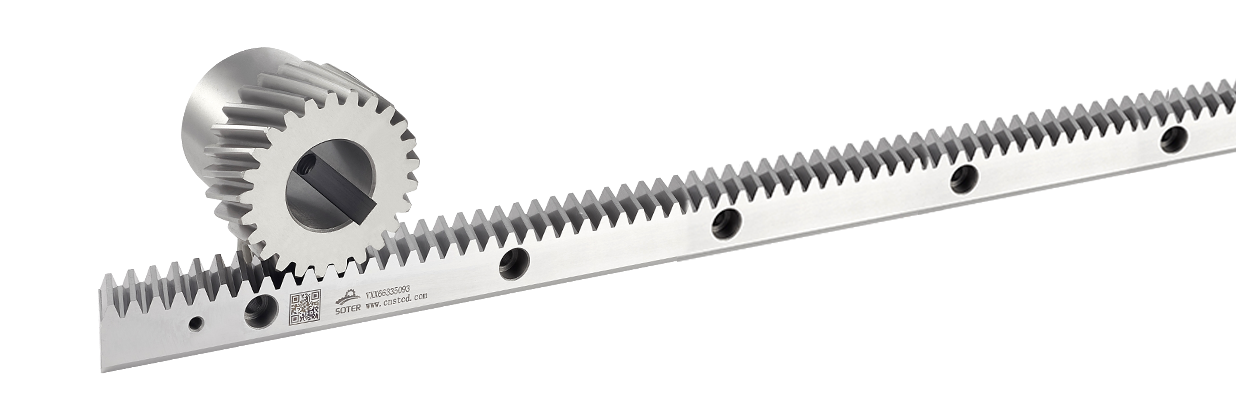

When it comes to selecting the right Straight Gear Rack Factory, the process can be as intricate as the gear racks themselves. Understanding the nuances of Straight Gear Rack Factory offerings is crucial for ensuring that the final product meets the specific requirements of your machinery. This article aims to provide a comprehensive guide to help you navigate the complexities of choosing the suitable Straight Gear Rack Factory for your needs.

The one step in selecting a Straight Gear Rack Factory is to identify the specific application for which the gear rack will be used. Different industries, such as automotive, aerospace, and robotics, have unique demands that a Straight Gear Rack Factory must be able to accommodate. For instance, a factory specializing in high-precision gear racks for the aerospace industry may not be a good choice for a robotics application that requires rapid, repetitive motion.

Once the application is clear, the next consideration is the material and construction of the Straight Gear Rack Factory's products. Steel is a common choice for its strength and durability, but other materials like aluminum or plastic may be more suitable for lighter applications. The Straight Gear Rack Factory should be able to provide gear racks in a variety of materials to cater to different load-bearing capacities and environmental conditions.

Precision is another critical factor when choosing a Straight Gear Rack Factory. High-precision gear racks are essential for applications where accuracy is paramount. The factory must have machinery and quality control processes in place to ensure that each gear rack meets high standards of precision. This includes not only the manufacturing process but also the post-processing, such as heat treatment and surface finishing, which can significantly affect the performance of the gear rack.

The Straight Gear Rack Factory's reputation and track record are also important. A factory with a history of delivering high-quality products on time and within budget is a valuable partner. Look for customer testimonials, case studies, and industry certifications to gauge the factory's reliability and commitment to quality.

Another aspect to consider is the Straight Gear Rack Factory's ability to customize its products. Standard gear racks may not always fit the specific needs of your machinery. A factory that offers customization services can create gear racks tailored to your exact specifications, ensuring a good fit and suitable performance.

The Straight Gear Rack Factory's after-sales service is equally important. A good factory will provide technical support, maintenance advice, and even repair services for their gear racks. This can save you time and money in the long run, as it ensures that your gear racks are always in good condition and ready for operation.

When it comes to pricing, it's essential to find a Straight Gear Rack Factory that offers competitive rates without compromising on quality. While it may be tempting to choose a cheap option, it's crucial to weigh the cost against the quality of the gear racks and the potential long-term savings in terms of maintenance and replacement costs.

Finally, consider the environmental impact of the Straight Gear Rack Factory's operations. A factory that adheres to sustainable manufacturing practices not only reduces its environmental footprint but also demonstrates a commitment to ethical business practices.

In conclusion, selecting the right Straight Gear Rack Factory involves a careful assessment of the factory's capabilities, reputation, customization options, after-sales service, pricing, and environmental practices. By considering all these factors, you can ensure that you choose a factory that will provide you with high-quality gear racks that meet your specific needs and contribute to the success of your machinery.