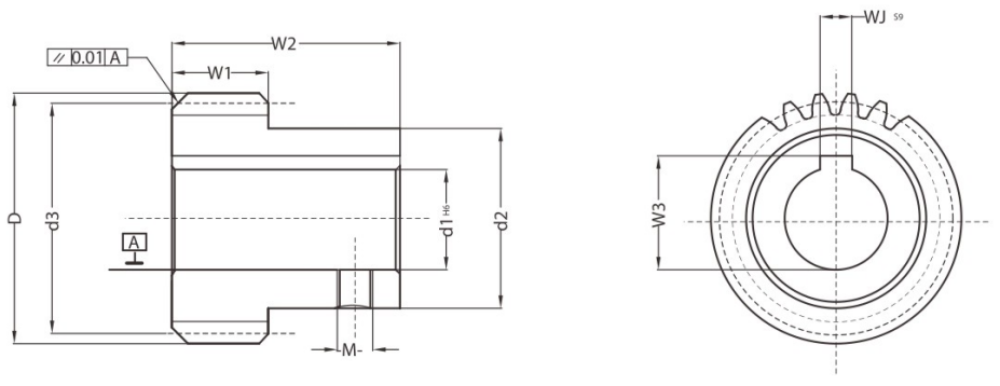

| Code | Module | Number Of Teeth | d1H6 | d2 | d3 | D | W1 | W2 | W3 | WJS9 | M | ||||

| YMCL302555 | 3 | 20 | 25 | φ50 | φ63.66 | φ69.66 | 30 | 55 | 28.3 | 8 | 8 | ||||

| YMCL302580 | 3 | 20 | 25 | φ50 | φ63.66 | φ69.66 | 30 | 80 | 28.3 | 8 | 8 | ||||

| YMCL303260 | 3 | 20 | 32 | φ55 | φ63.66 | φ69.66 | 28 | 60 | 35.3 | 10 | 8 | ||||

| YMCL303255 | 3 | 25 | 32 | φ66 | φ79.57 | φ85.57 | 30 | 55 | 35.3 | 10 | 8 | ||||

| YMCL303565 | 3 | 25 | 35 | φ55 | φ79.57 | φ85.57 | 28 | 65 | 38.8 | 10 | 8 | ||||

| YMCL304080 | 3 | 25 | 40 | φ70 | φ79.58 | φ85.58 | 39 | 80 | 43.3 | 12 | 12 | ||||

| YMCL303282 | 3 | 25 | 32 | φ66 | φ79.57 | φ85.57 | 30 | 82 | 35.3 | 10 | 8 | ||||

| YMCL304084 | 3 | 30 | 40 | φ68 | φ95.49 | φ101.5 | 29 | 82 | 43.3 | 12 | 8 | ||||

| YMCL404550 | 4 | 22 | 45 | φ65 | φ93.37 | φ101.4 | 40 | 50 | 38.3 | 10 | 8 | ||||

| YMCL403575 | 4 | 24 | 35 | φ55 | φ101.86 | φ109.9 | 40 | 75 | 38.3 | 10 | 8 | ||||

| YMCL404075 | 4 | 24 | 40 | φ62 | φ101.86 | φ109.9 | 40 | 75 | 43.3 | 12 | 10 | ||||

| YMCL404080 | 4 | 25 | 40 | φ80 | φ106.103 | φ114.103 | 42 | 80 | 43.3 | 12 | 10 | ||||

Zhejiang Soter Transmission Technology Co., Ltd. founded in 2006, is located in Wenling City, a coastal city in eastern Zhejiang with beautiful scenery and convenient transportation. It is a famous production base for auto parts and automation parts in the country.

Zhejiang Soter Transmission Technology Co. Ltd. is a professional OEM 3M DIN6 Ground Helical Gear supplier with many years of experience in 3M DIN6 Ground Helical Gear. During these years of 3M DIN6 Ground Helical Gear processing and manufacturing, we have continuously developed new processes and introduced new technologies, ushering in a new era in the rack transmission industry, a new milestone. After years of development, we have absorbed manufacturing experience and established a strong technical research and development team.

Total floor area

Annual production

Employees

Let’s create something amazing together.

Customization

We have a strong R&D team, and we can develop and produce products according to the drawings or samples the customers offer.

Cost

Our racks from the blank to the finished product process production process are completed by their factories, factory direct sales of good quality and low price.

Quality

We have our production facilities and advanced testing equipment in the industry to ensure the quality of our products.

Capacity

With an annual production capacity of over 1 million racks, we can meet the needs of customers with different purchasing volumes.

Service

We focus on developing high-quality products for top-end markets. Our products are in line with international standards and are mainly exported to Europe, America, Japan, and other destinations around the world.

Shipment

We are only 200 kilometers from the port of Beilun, making it very easy to export.

Don't hesitate to contact when you need us!

We’re a reliable partner that shapes our expertise into success for your project.