Industry News

Mar 07, 2025

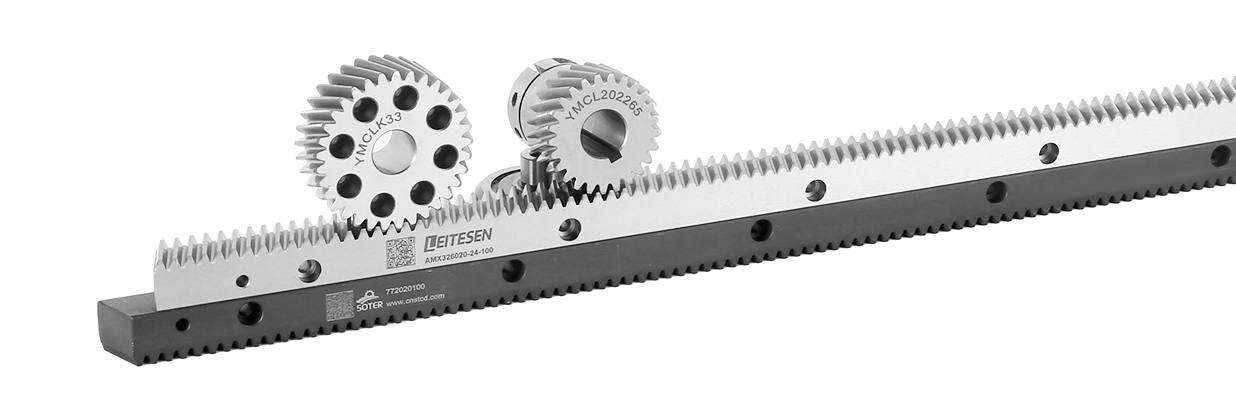

The manufacturing industry is constantly evolving, with a heightened focus on the efficiency and longevity of its components. Among these, the Helical Toothed Gear Racks Factory stands out as a provider of machinery critical parts that is integral to the smooth operation of various industrial systems. This article will explore the durability and reliability of the products manufactured by Helical Toothed Gear Racks Factories, delving into the factors that contribute to their robustness and dependability.

The durability of Helical Toothed Gear Racks Factory products is a testament to the rigorous standards and quality control measures implemented throughout the manufacturing process. Helical Toothed Gear Racks, known for their helical teeth design, offer several advantages over their straight-toothed counterparts, including reduced noise and smoother operation. The Helical Toothed Gear Racks Factory ensures that these benefits are consistently achieved by employing advanced materials and precision engineering techniques.

One of the key aspects of the Helical Toothed Gear Racks Factory's commitment to durability is the selection of high-quality materials. The factory sources materials that are resistant to wear and tear, such as high-grade steel and alloys, which can withstand the demands of heavy-duty applications. These materials are not only strong but also can maintain their integrity over extended periods of use, contributing to the longevity of the Helicaled Tooth Gear Racks produced by the factory.

The reliability of Helical Toothed Gear Racks Factory products is further enhanced by the precision manufacturing processes employed. The factory utilizes machinery and technology to ensure that each gear rack is manufactured to the exact specifications. This precision engineering reduces the occurrence of defects and inconsistencies, ensuring that the Helical Toothed Gear Racks perform as intended in real-world applications.

In addition to the materials and manufacturing processes, the Helical Toothed Gear Racks Factory also focuses on the design of its products. The helical teeth are designed to distribute the load evenly across the tooth surface, reducing stress concentrations that can cause premature failure. This design feature, combined with the factory's commitment to continuous improvement, results in Helical Toothed Gear Racks that are both durable and reliable.

The Helical Toothed Gear Racks Factory also places a strong emphasis on testing and validation. Each batch of gear racks undergoes rigorous testing to ensure they meet the factory's high standards for performance and reliability. This includes tests for load capacity, wear resistance, and operational efficiency. By subjecting the Helical Toothed Gear Racks to these tests, the factory can identify any potential issues and address them before the products are shipped to customers.

Furthermore, the factory's commitment to sustainability and environmental responsibility is evident in its efforts to reduce waste and improve the efficiency of its operations. This not only reduces the environmental footprint of the Helical Toothed Gear Racks Factory but also contributes to the overall cost-effectiveness of its products.

In conclusion, the durability and reliability of Helical Toothed Gear Racks Factory products are a result of a combination of high-quality materials, precision engineering, and rigorous testing. The factory's dedication to well in every aspect of its operations ensures that the Helical Toothed Gear Racks it produces are up to the task of withstanding the demands of challenging industrial environments. As a result, customers can have confidence in the performance and longevity of the Helical Toothed Gear Racks Factory's products, knowing that they are backed by a commitment to quality and reliability.

Related Products

Call Us :

+86-13758631128

E-mail :

sttc@cnstcd.com

Add :

31 piazza road, ruoheng town, wenling city, taizhou city, zhejiang province, China.